Rubber expansion joint

This kind of expansion joint is usually used in order to damp undesired vibrations caused by pumps, and prevent them to reach to the pipe line accessories

Applications

ENETAF SANE rubber expansion joints cover a vast usage domain of following situations

Different fluids such as strong acids, chemical solvents, petroleum derivatives & etc

High temperature situations up to 150 °C

High pressure or vacuum situations

Different axial , lateral and angular movements

Excellent damping of vibrations , noises and water hammers in the pipeline

Rubber expansion joints are able to be designed for different chemical, gas, petroleum, sewage and abrasive mediums. Also there are specific materials which can resist against chemical oils, sunshine, acids , smoke and ozone

Rubber expansion joints could be reinforced against pressure with steel rings around or within rubber body or against vacuum with vacuum rings inside the rubber convolution

We can damp relatively large movements with two or more arches in rubber expansion joints. When having multiple arches, the possible movement is approximately equal to movement of one arch times by number of arches , so we can design number of arches in accordance with the required movement

ENETAF SANE manufactures its rubber expansion joints in two forms of swivel flange ( bladdery rubber expansion joints ) and integrated flange ( autoclave rubber expansion joints ) . Bladdery ones are mass produced in sizes ranging from 1 to 12 inches . By the way integrated flange rubber expansion joints are custom built in sizes ranging from 12 to 144 inches and based on client’s need shall be designed plain or with tie rods . Flange specifications shall be selected exactly based on client’s need. ENETAF SANE is capable of manufacturing rubber expansion joints with one , two and three arches

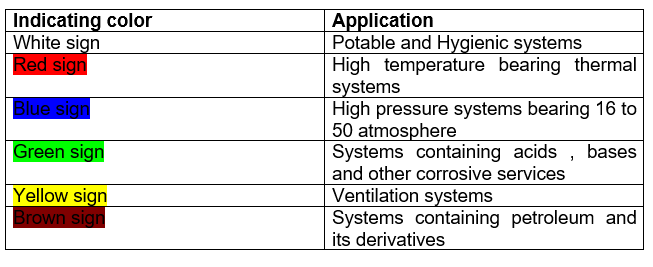

Different rubber materials could be applied in order to comply with different fluids and therefore we can cover a wide range of applications same as table below

Filled arch expansion joints

This kind of rubber expansion joint is being applied with the purpose of decreasing flow chaos and turbulence as well as preventing solid external substances to get stuck within the rubber convolution . Pay attention that , they shall not be used unless really needed , because exploiting a filled arch in itself decreases expansion joint flexibility up to 50%

Important points

Tie rods are not able to replace anchors in a pipeline , by the way in some special cases we can substitute a tie rod with an anchor

Rubber expansion joints are not designed somehow to completely resist thrust forces and also if there is any certain movement , tie rods shall be contrived . An additional safety factor is also considered in order to prevent unexpected failures and minimize probable risks

System control unit contains at least two tie rods with triangular lugs , hexagonal nuts and steel and/or rubber washers/gaskets. Size and length of tie rods are designed according to test pressure and other project requisitions

it is so much important to install and set all tie rods before expansion joint installation. It is necessary not to change tie rods regulations during expansion joints life time , and care must be taken about nuts , because they may get gradually unclenched in result of existing vibrations. In addition , we shall note that tie rods are not able to protect the expansion joint against lateral movements , thus pipeline shall be completely supported in lateral direction. It might even be needed to limit axial movements in order to prevent stresses