Rubber Hose

Rubber hose is widely used in conveying systems for both pipeline and bends and in systems where a degree of natural flexibility is required. Its particular properties also make it ideal for use in systems where the material being conveyed may be friable, abrasive, or cohesive. Its natural flexibility makes it ideal for use in vacuum off-loading applications, mobile conveying systems, and for joining pipeline sections in situations where standard pipeline bends will not match the geometry required

Erosive Wear and Particle Degradation

Rubber hose has the capability of withstanding erosive wear better than steel pipeline in certain situations. Although the hardness of the surface material is generally much lower than that of alternative metal surfaces, and of the particles impacting against the surface, it derives its erosive wear resistance from the fact that it is able to absorb much of the energy of impact by virtue of its resilience. By the same mechanism, the impact energy of friable materials can also be absorbed and so particle degradation may also be reduced appreciably

Synthetic Rubber Hose

Rubber hoses are designed for specific fluid, temperature, and pressure ranges and are provided in various specifications. Rubber hoses consist of a minimum of three layers: a seamless synthetic rubber tube; one or more reinforcing layers of braided or spiraled cotton, wire, or synthetic fiber; and an outer cover. The inner tube is designed to withstand the attack of the fluid that passes through it. The braided or spiraled layers determine the strength of the hose. The more layers there are, the greater the pressure rating is. Hoses are provided in three pressure ranges: low, medium, and high. The outer cover is designed to withstand external abuse and contains identification markings

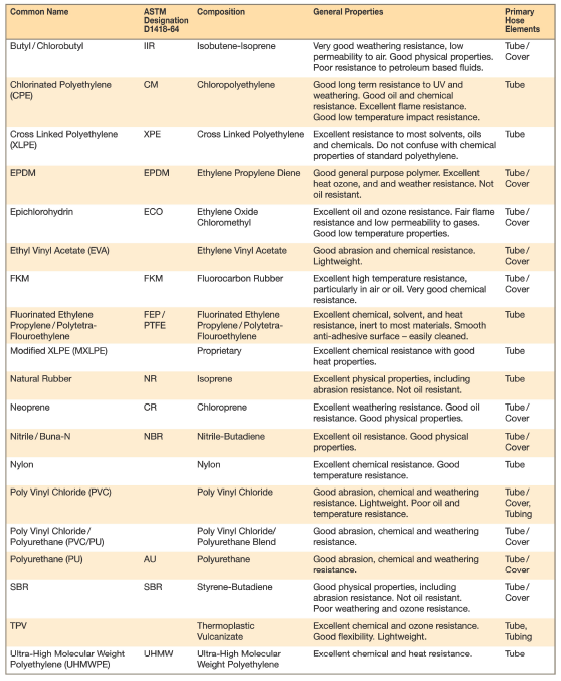

Rubber Hose Chemical Resistance

انتخاب نوع متریال شلنگ های لاستیکی براساس سیال( خوردگی ) و دمای طراحی صورت می گیرد.

برای اطلاعات بیشتر به کاتالوگ مراجعه شود.